- Home

- Ramp

- Our strength

- Production

- Machine park

- Injection

- Video

- Assembling

- Tool workshop

- Contact Us

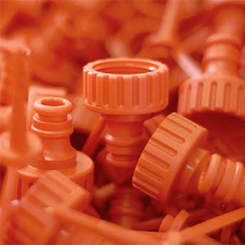

For this more than 25 years we managed to establish strong market position in a manufacturing and trade. In 2005 year RAMP change from Enterprise into company Ltd. At present our main business unit is INJECTION SHOP. We are manufacturing for customerŌĆÖs orders many plastic items which are made from diverse raw materials. The name of our company RAMP is also a brand for our own market product - complete irrigation system for gardens. This product line consist of various elements like: hose quick-connectors, taps, hand sprays, sprinklers, etc.

|

|

|

|

|

|

|

|

|

|

|

|

Strengths of our company are experience in plastic processing and finishing business, modern injection machines, new technologies, but the most important is qualified personnel.

|

|

|

|

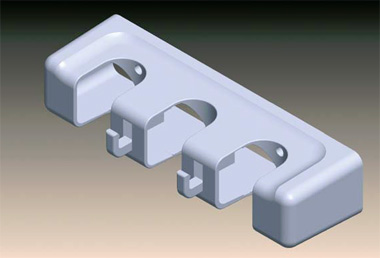

Range of goods we manufacture for orders are from about 2g to almost 1000g. We work on such plastic material as ABS, PP, PA, POM, PC, PS, PBT, rubbers and also composites.

|

|

|

|

|

|

| Machine | Clamp force (kN) | Distance between tie-bars (mm) | Max. plasticising rate (for PS g) |

|---|---|---|---|

| Arburg Allrounder 221K | 350kN | 221/221 | 45g |

| Arburg Allrounder A 270 U | 400kN | 270/270 | 40g |

| Arburg Allrounder 270C | 500kN | 270/270 | 89g |

| Arburg Allrounder 320C | 500N | 320/320 | 77g |

| Battenfeld HM 800/350 | 800kN | 420x370 | 177g |

| Arburg Allrounder 420C | 1000kN | 420/420 | 127g |

| Battenfeld H1000 double component injection |

1000kN | 470/420 | 169g + 36g |

| KraussMaffei 125/520 + Robot Wittmann W-811 |

1250kN | 470/470 | 288g |

| Battenfeld HM 1300/750 + Robot Wittmann W-811 |

1300kN | 520/470 | 375g |

| KraussMaffei CX 160-750 + Robot Wittmann W-818T | 1600kN | 520/520 | 412g |

| Wittman-Battenfeld Eco power B-180/750 + Robot Wittmann W-818T | 1800kN | 570/520 | 376g |

| KraussMaffei CX200-1000 + Robot Wittmann W-811 |

2000kN | 560/560 | 549g |

| KraussMaffei PX320 + Robot Wittmann W-833 |

320kN | 720/670 | 792g |

| Wittmann Battenfeld MacroPower 400 + Robot Wittmann W-833 |

4000kN | 750x900 | 1657g |

| Engel Duo E500 + Robot Viper 20 | 5000kN | 910/830 | 1960g |

| Wittmann Battenfeld MacroPower 650/5100 + Robot Wittmann W-833 | 6500kN | 1100/950 | 2532g |

| Clean Room | produkcja czysta | ||

| Arburg Golden Electic e370 + Robot Arburg Multilift |

600kN | 370/370 | 54g |

| Arburg Allrounder V275 Maszyna pionowa ze sto│em obrotowym |

250kN | 270/270 | 31g |

| KraussMaffei PX51 + Robot Wittmann W-811 |

500kN | 720/670 | 35g |

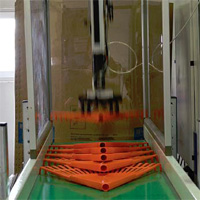

Our injection Shop is working 24 hour per day 7 days per week. Each machine has been connecting with material dryer and dosing unit. Injection shop is equipped with belt conveyors, separators, temp. controllers, recycling machines.

n our injection shop we produce items for such customers as: GE POWER CONTROLS S.A., Valvex S.A., AMII Sp. z o.o., Matt Sp. z o.o. and others.

|

|

|

|

|

|

For special applications we use ultrasonic welding technology.

|

|

|

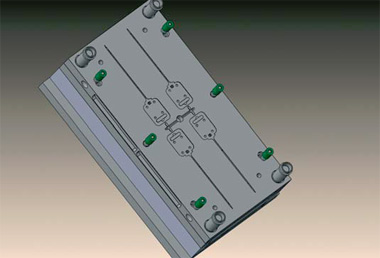

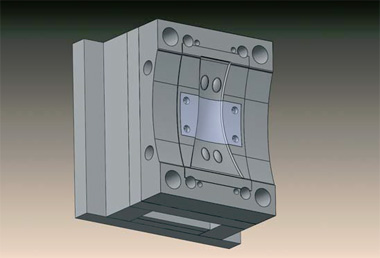

RAMP company has own mold manufacturing workshop for molds maintenance and service on place. More over we offer assembling, warehousing and transport to customer place. We are looking forward to start cooperating with you. Board of RAMP sp. z o.o.

|

|

|

|

|

|

RAMP Sp. z o.o.

Poland, 92-720 Łódź

Jugosłowiańska st. No. 25a

Tel.: +4842 6484317 Fax: +4842 6484656

email: biuro@ramp.pl